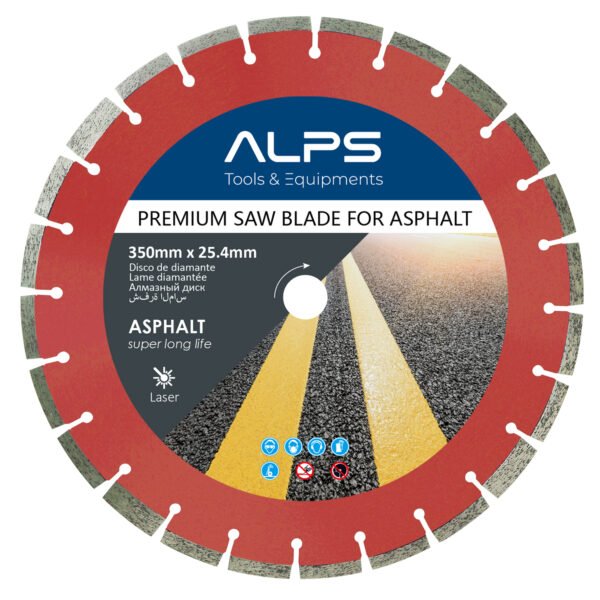

Product Overview

Heavy-Duty Cutting Power for Industrial Applications

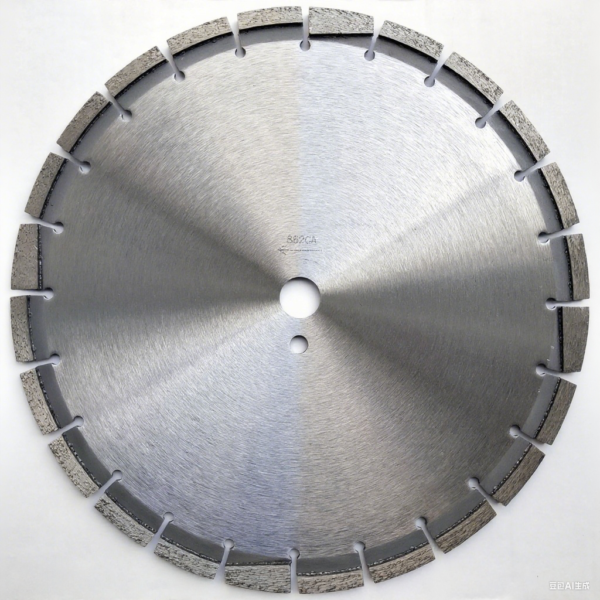

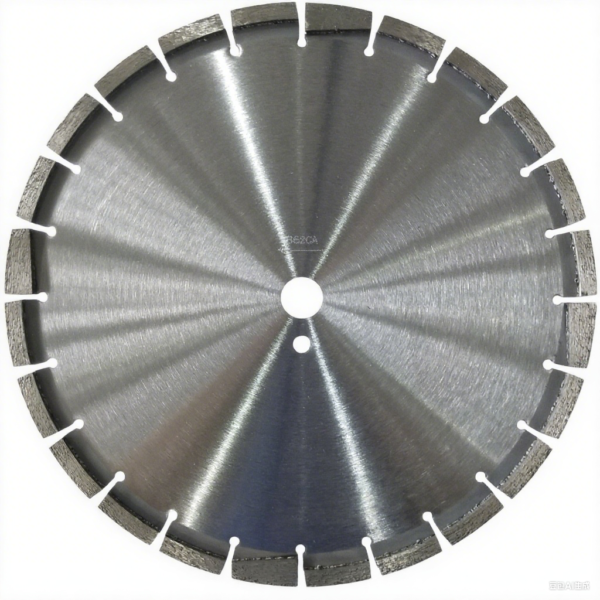

Engineered for extreme material removal in tough environments, the 350MM Laser Welded Wide Cut / Loop Cut Diamond Blade combines rugged laser-welded construction with a specialized undercut segment design to deliver unmatched performance in deep, wide cutting tasks. Available in 6mm, 8mm, 10mm, 12mm thicknesses, this blade is optimized for creating wide kerfs (6-12mm) and loop cuts in concrete, asphalt, reinforced steel, and natural stone. Ideal for industrial saws, excavator-mounted cutters, 20KW Floor saw.

Core Engineering Features

1. Laser-Welded Durability for Heavy Loads

- 100% Industrial Laser Welding: Secures diamond segments to the 350mm steel core with precision heat fusion, creating a bond strength 30% higher than traditional brazing. Eliminates segment loss even under prolonged high-torque operations (max 10,000 RPM).

- Reinforced Core Design: Thickened steel substrate (5mm core) reduces flexing during deep cuts, ensuring straight cutting paths and minimal vibration.

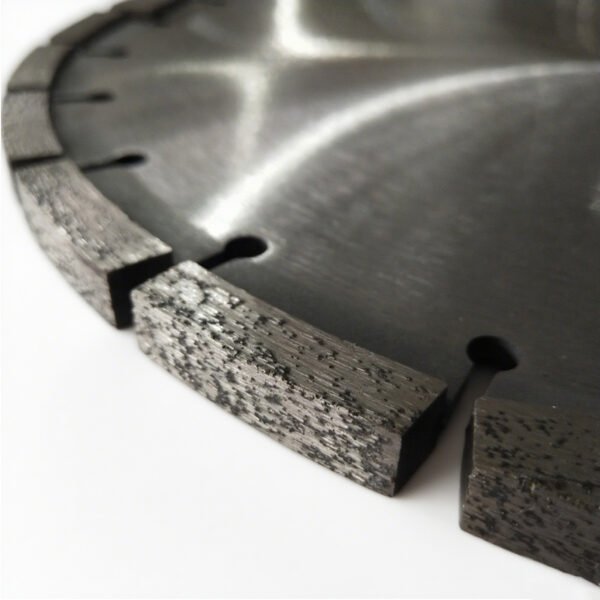

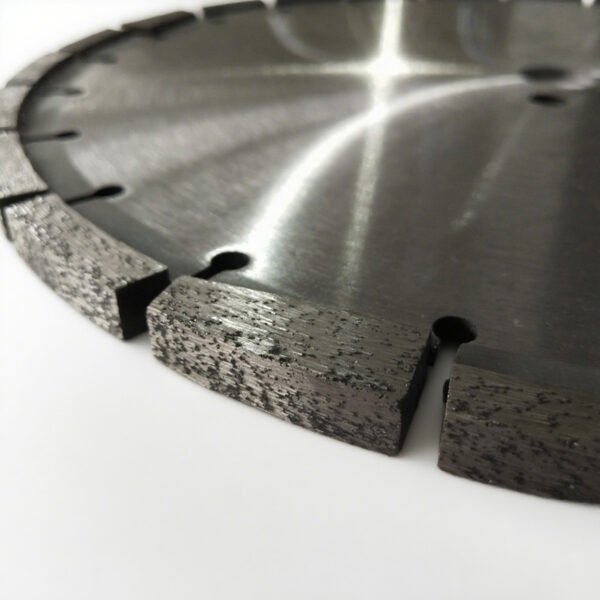

2. Undercut Segments & Segmented Pattern

- Aggressive Undercut Geometry: Deeply recessed segment bases (5mm undercut) increase chip clearance, allowing faster removal of concrete debris, steel shavings, and stone dust. Reduces blade clogging by 40% in wet cutting conditions.

- Alternating Segment Layout: Spaced 8mm apart with staggered heights, the segmented pattern creates a self-sharpening effect. Fresh diamond grit is continuously exposed, maintaining cutting speed through abrasive materials like reinforced concrete (C40/C50 strength).

3. Wide Kerf Capability

- 6-12mm Cutting Thickness Options:

- 6mm/8mm: For precise wide cuts in thin-walled concrete (e.g., precast panels, pipe trenches)

- 10mm/12mm: Ideal for heavy-duty loop cuts in reinforced slabs, asphalt roads, and granite blocks

- Dual-Purpose Design: Switch between “Wide Cut” for material removal and “Loop Cut” for circular/arched cuts without blade changes.

Technical Specifications

| Parameter | Details |

| Diameter | 350mm |

| Thickness Options | 6mm, 8mm, 10mm, 12mm |

| Arbor Size | 25.4mm (standard) / 30mm (heavy-duty option) |

| Max RPM | 10,000 (6-8mm) / 8,500 (10-12mm) |

| Segment Height | 15mm (provides 12mm effective cutting depth) |

| Material Compatibility | Concrete (reinforced/non-reinforced), asphalt, granite, basalt, steel profiles |

| Cutting Depth | Up to 120mm (with 15mm segment height) |

Ideal Applications

1. Construction & Demolition

- Reinforced Concrete Cutting: Deep loop cuts for foundation removal, bridge deck profiling, and column sectioning

- Asphalt Pavement: Wide trenches for utility installation (water pipes, electrical conduits) with 12mm thickness blades

- Precast Concrete: Precision wide cuts on concrete slabs without edge cracking (6mm/8mm thickness recommended)

2. Stone Fabrication

- Granite & Basalt Slabs: Heavy-duty splitting of 50mm+ thick stone blocks using 10mm/12mm blades

- Monument Cutting: Curved loop cuts for (monuments) and architectural stone elements

3. Industrial Machinery

- Excavator-Mounted Saws: High-torque compatibility for hydraulic cutting attachments in demolition robots

- Stationary Block Saws: Consistent performance in automated stone cutting lines

Performance Advantages

✅ Rapid Material Removal: Undercut segments increase chip evacuation rate by 50%, reducing cutting time by 20% vs standard blades

✅ Extended Service Life: Laser-welded segments resist impact damage; 25% longer life in abrasive environments

✅ Safety-Focused Design: Balanced core minimizes kickback risk; segmented pattern reduces heat buildup during wet/dry cutting

✅ Versatile Thickness Range: Single diameter (350mm) with 4 thickness options covers 90% of industrial wide-cut needs

Usage & Maintenance Tips

Cutting Recommendations

- Wet Cutting Only: Always use with water cooling system (5-8L/min flow) to prevent overheating and enhance blade life

- Break-In Procedure: Run at 50% speed for 2 minutes before first use to align segments

- Load Control: Maintain 5-10mm per pass feed rate for 10-12mm thick blades to avoid motor overload

Storage & Care

- Vertical Storage: Hang blades by arbor hole to prevent core warping

- Post-Use Cleaning: Remove concrete/stone residue with wire brush; avoid acidic cleaners

Why Choose Our Wide Cut Diamond Blade?

- Heavy-Duty Certification: Tested to cut C50 concrete with 16mm steel rebar at 80mm depth without segment damage

- Factory-Balanced Precision: Each blade undergoes dynamic balancing to ≤50g·mm vibration tolerance

- Custom Arbor Options: Available with 30mm arbor for heavy-duty Demag/Komatsu saws (contact for OEM specifications)

Power Through the Toughest Materials – the 350mm Laser Welded Wide Cut Blade delivers unmatched performance in industrial cutting applications. Choose your thickness (6-12mm) based on project demands and experience zero-compromise cutting efficiency.

Reviews

There are no reviews yet.