Product Overview

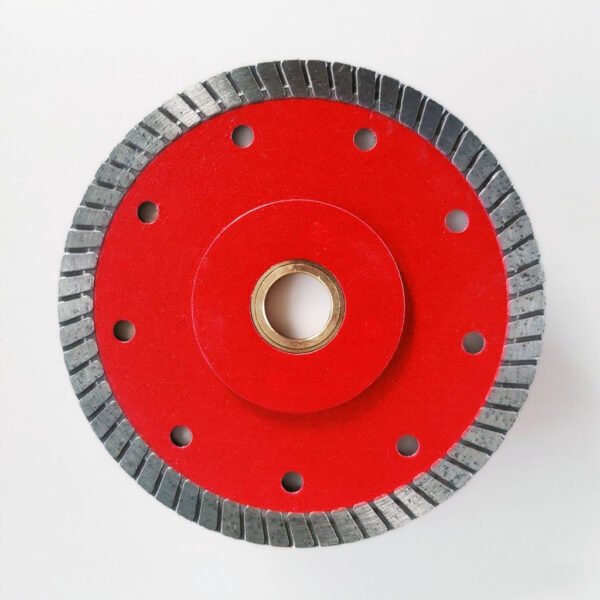

Engineered for professional tile artisans and precision-driven projects, the Super Thin Turbo Continuous Rim Sintered Diamond Blade combines advanced sintering technology with a sleek continuous rim design to deliver mirror-smooth cuts on all tile materials. With an ultra-thin profile (1.2-2.0mm cutting edge) and turbo-engineered airflow channels, this blade minimizes chipping, maximizes cutting speed, and ensures consistent performance across sizes from 75mm to 350mm. Ideal for high-gloss tiles, delicate mosaics, and large-format slabs where surface finish is critical.

Core Technological Advantages

1. Sintered Diamond Matrix for Unmatched Durability

- High-Pressure Sintering Process: Diamond grit (20/25 mesh premium grade) is fused with a proprietary metal bond under 800+°C and 500+ MPa pressure, creating a homogenous, wear-resistant cutting edge that retains sharpness 40% longer than welded blades.

- Zero Segment Loss: Fully sintered construction eliminates weak points between segments, ensuring structural integrity even at maximum RPM and under heavy load.

2. Continuous Rim Design for Glass-like Finishes

- 1.2-2.0mm Micro-Thin Edge: Produces kerf widths as narrow as a razor, reducing material waste and enabling intricate cuts on 3mm-30mm thick tiles.

- Polished Continuous Rim: Smooth cutting surface glides through glazed, porcelain, and natural stone tiles without chipping, eliminating the need for post-cutting (polishing). Perfect for backsplashes, shower niches, and decorative edging.

3. Turbo Cooling Channels for Heat Management

- Patented Airflow Grooves: Strategically placed turbo grooves enhance air circulation, reducing friction heat by 30% during dry cutting. Maintains blade stability and prevents thermal damage to delicate tile surfaces.

- Balanced Steel Core: Precision-machined core minimizes vibration at high speeds (up to 18,000 RPM), ensuring controlled cuts and reduced user fatigue.

Available Sizes & Technical Specs

| Diameter (mm) | Arbor Size (mm) | Thickness (mm) | Max RPM | Ideal Application |

| 75-125 | 16/20 | 1.2 | 25,000 | Handheld grinders for mosaic/edging work |

| 150-230 | 20/25.4 | 1.86 | 20,000 | Table saws & rail cutters for standard tiles |

| 300-350 | 25.4/30 | 2.0 | 12,000 | Industrial bridge saws for large-format slabs |

Compatible Materials

Perfect for cutting:

- Glazed Ceramic Tiles: High-gloss finishes, subway tiles, and decorative mosaics

- Porcelain & Full-Body Tiles: Dense porcelain (up to 2800kg/m³ density) and through-body tiles

- Natural Stone: Marble, travertine, limestone (wet cutting recommended for soft stones)

- Engineered Stone: Sintered stone, quartz panels, and terrazzo tiles

- Glass Tiles: Scratch-free cutting on 4-12mm glass mosaic sheets

Applications

Professional Tile Installation

- Decorative Patterns: Herringbone, chevron, and basketweave layouts requiring mitered/45° angle cuts

- Large-Format Tiles: 1200x2400mm+ slabs cut with zero edge chipping for seamless floor/wall installations

- Backsplash Details: Precise cutouts for outlets, switches, and custom edge profiles

Industrial Processing

- Tile Factories: High-volume cutting of pre-finished tiles with consistent dimensional accuracy (±0.1mm tolerance)

- Stone Fabrication: Profiling of countertop edges and vanity tops from sintered stone panels

DIY & Renovation

- Bathroom Remodels: Clean cuts for shower wall tiles and niche insets

- Kitchen Upgrades: Perfectly fitted backsplash tiles around cabinets and appliances

Optimal Usage Guidelines

Cutting Methods

- Dry Cutting: Use with dust extraction for quick onsite cuts; ideal for small projects (max 10mm tile thickness)

- Wet Cutting: For tiles >10mm thick or extended use; connect to water cooling system to double blade life and enhance finish

Safety & Maintenance

- Speed Matching: Always use within specified RPM range; reduce speed by 20% for soft stones (e.g., marble)

- Storage: Store in anti-corrosive packaging in a dry environment; avoid contact with acidic substances

- Break-In Procedure: Lightly cut a scrap tile for 10 seconds before first use to activate the cutting edge

Why Choose Our Sintered Continuous Rim Blade?

✅ Perfect Finish Guarantee: 99.7% chip-free cutting on glazed surfaces (tested on 3mm ceramic tiles)

✅ Time Savings: Cuts 25% faster than standard continuous rim blades on dense porcelain

✅ Cost Efficiency: 2x longer service life compared to laser-welded alternatives in professional use

✅ Universal Fit: Compatible with Makita, Dewalt, Bosch, and all major tile cutting machine brands

Elevate your tile projects to gallery-worthy standards – available in all sizes from 75mm hobbyist grinders to 350mm industrial saws. Contact our technical team for custom arbor configurations or bulk pricing for contracting teams!

Reviews

There are no reviews yet.