TCT SAW BLADE FOR INDUSTRIAL PLYWOOD CUTTING – INDUSTRIAL GRADE PERFORMANCE REDEFINED

Engineered for the rigors of heavy-duty plywood processing, this Industrial-Grade TCT (Tungsten Carbide Tipped) Saw Blade stands as a pinnacle of precision and durability. Crafted with high-quality tungsten carbide tips, it delivers exceptional wear resistance, ensuring consistent cutting performance even through thick, multi-layered industrial plywood—ideal for high-volume production environments where reliability is non-negotiable.

The blade features an ATB (Alternate Top Bevel) tooth design, a strategic choice for plywood cutting. This tooth configuration alternates bevels on alternating teeth, creating ultra-clean, splinter-free cuts across both the face and edges of plywood sheets. Whether dealing with standard plywood, veneered panels, or moisture-resistant industrial grades, the ATB teeth minimize tear-out, reducing the need for post-cut sanding and streamlining your workflow.

Rigorously MAP (Material Analysis and Performance) tested, this blade has undergone stringent evaluations under real-world industrial conditions. Tests validate its ability to maintain cutting sharpness over extended use, resist heat buildup during prolonged operation, and handle the variable density of plywood cores—from softwood to hardwood layers. This certification ensures it meets the strict standards of industrial manufacturing, woodworking factories, and large-scale carpentry operations.

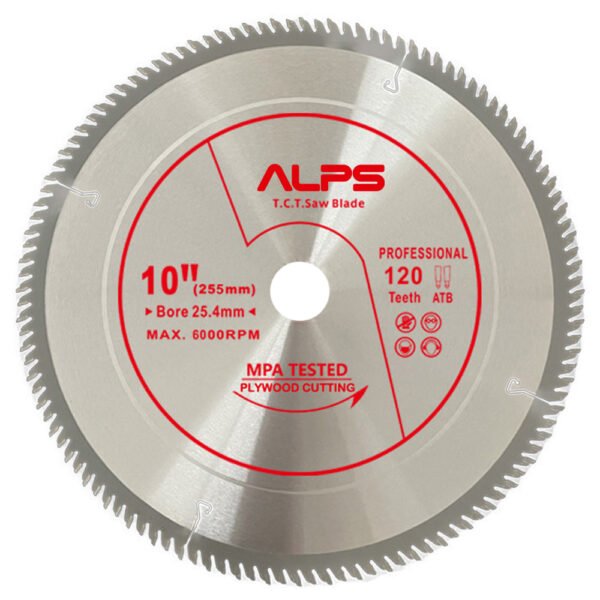

Specifications

| DIA. | KREF | BORE | TEETH |

| 10″(255mm) | 3.2 | 25.4mm | 100/120 |

| 12″(305mm) | 3.2 | 30mm | 100/120 |

Compatible Machines:

Designed to integrate seamlessly with industrial-grade equipment, this blade is optimized for use with:

- Panel saws (vertical and horizontal models) for high-speed, large-sheet plywood cutting.

- CNC routers and beam saws in automated production lines, where precision and repeatability are critical.

- Circular saws and table saws used in heavy-duty woodworking shops, adapted for industrial plywood processing.

Ideal Use Scenarios:

Perfect for environments demanding efficiency and accuracy, including:

- Furniture manufacturing facilities, where clean cuts on plywood panels are essential for cabinetry, shelving, and structural components.

- Construction material production, processing industrial plywood for flooring, wall panels, and formwork.

- Packaging and crating operations, cutting plywood sheets into custom sizes for heavy-duty shipping containers.

- Woodworking factories handling bulk plywood orders, where the blade’s durability reduces downtime from frequent blade changes.

Elevate your industrial plywood cutting with a blade that combines industrial-grade strength, precision engineering, and proven performance—because in high-stakes production, every cut counts.

Reviews

There are no reviews yet.