Professional TCT Saw Blade for Precision Metal Cutting

Engineered for superior performance in industrial metal machining, our TCT Saw Blade for Metal Cutting combines German – certified quality, advanced Triple Chip Grind (TCG) tooth technology, and rugged construction to deliver unmatched precision, efficiency, and durability across all metal cutting applications. Trusted by professionals worldwide, this blade is the ultimate solution for demanding metalworking tasks.

Key Features & Benefits

1. German MPA Tested Excellence

Rigorously tested and certified by the German Materialprüfungsanstalt (MPA), this blade meets the strictest international standards for material integrity, dimensional accuracy, and operational safety. The MPA certification guarantees consistent performance even under high – stress cutting conditions, making it ideal for critical industrial applications where precision and reliability are non – negotiable.

2. Triple Chip Grind (TCG) Tooth Design

Featuring the specialized Triple Chip Grind (TCG) tooth design, our saw blade is engineered with an alternating pattern of flat – top and chamfered teeth. The flat – top teeth execute the primary cutting action, providing stability and accuracy while minimizing splintering and tear – out on the cut surface. Meanwhile, the chamfered teeth efficiently break down and clear away debris, ensuring a smooth and continuous cutting process. This unique tooth configuration is especially effective for cutting tough metals, reducing the risk of clogging and heat buildup, and delivering a clean, burr – free finish with minimal post – processing required. Whether you’re working with hard stainless steel or high – carbon alloys, the TCG design significantly enhances cutting efficiency and extends blade life.

3. Professional – Grade Construction

- TCT (Tungsten Carbide – Tipped) Edge: The blade is equipped with premium tungsten carbide tips bonded to a high – strength steel body, offering exceptional hardness and wear resistance for long – lasting cutting performance.

- Vibration – Damped Design: A balanced, low – noise structure minimizes vibration during operation, ensuring stable cuts and protecting both the machine and the workpiece from damage.

- Heat – Resistant Build: Engineered to withstand high – speed cutting without compromising edge retention, the blade maintains sharpness and precision even during extended use.

Versatile Metal Cutting Solutions

Ideal for a wide range of metal materials and profiles:

- Ferrous Metals: Carbon steel, stainless steel, alloy steel, tool steel

- Non – Ferrous Metals: Aluminum, copper, brass, titanium

- Metal Forms:

-

- Bars (round, square, hexagonal)

-

- Pipes & tubes (hollow sections)

-

- Sheets & plates (flat stock)

-

- Angles, channels, and extruded profiles

Suitable for use on various cutting machines, including:

- Circular saws

- Chop saws

- CNC machining centers

- Automatic cutting lines

Performance Advantages

- Precision Cutting: Achieves tight dimensional tolerances with a narrow kerf, ensuring accurate cuts for critical metal components.

- High – Speed Efficiency: Optimized Triple Chip Grind tooth geometry allows for faster feed rates while maintaining superior cut quality, reducing cycle times in high – volume production.

- Extended Service Life: The combination of TCG teeth and TCT construction significantly reduces wear, outlasting standard metal cutting blades and lowering operational costs.

- Safety – First Design: The MPA – certified design prioritizes user safety, with features that minimize kickback and heat – related risks during operation.

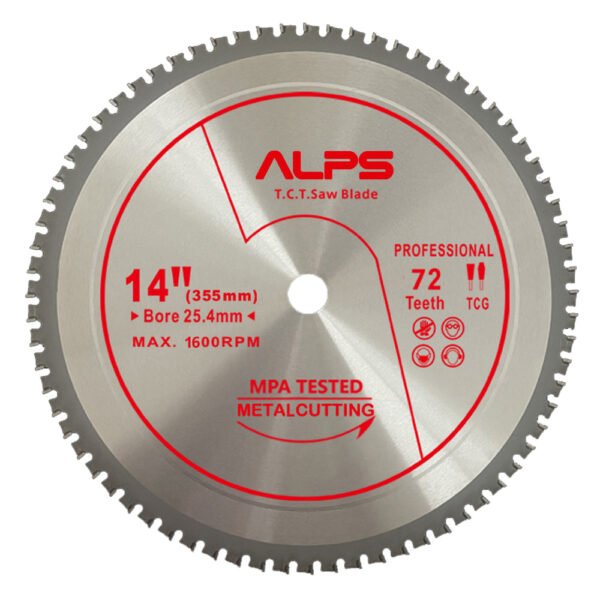

Technical Specifications

- Material: Tungsten Carbide Tips (TCT) + Heat – Treated Steel Body

- Tooth Type: Triple Chip Grind (TCG)

- Certification: German MPA Tested

- Recommended Speed: 2,000–8,000 RPM (adjust based on machine capacity and material hardness)

- Compatible Machines: Standard and industrial – grade cutting equipment

- Dimensions as below:

| DIA. | KREF | BORE | TEETH |

| 4″(105mm) | 1.8 | 20mm | 24 |

| 4″(110mm) | 1.8 | 20mm | 24 |

| 5″(125mm) | 1.8 | 20mm | 24 |

| 7″(185mm) | 2 | 25.4mm | 36/48 |

| 9″(230mm) | 2.2 | 25.4mm | 48 |

| 10″(254mm) | 2.2 | 25.4mm | 60 |

| 12″(305mm) | 2.2 | 25.4mm | 60 |

| 14″(355mm) | 2.4 | 25.4mm | 66/72/80/90 |

Trusted by Industrial Professionals

Whether you’re fabricating steel structures, machining automotive components, or producing precision metal parts, our TCT Metal Cutting Saw Blade delivers the performance and reliability that industrial workshops and manufacturing lines demand. The German – tested quality and professional – grade design make it the go – to choice for applications where failure is not an option.

Upgrade your metal cutting operations today—experience the difference of a blade built for precision, power, and productivity.

Order Now and discover why professionals worldwide rely on our TCT saw blades for their most challenging metalworking tasks.

Reviews

There are no reviews yet.