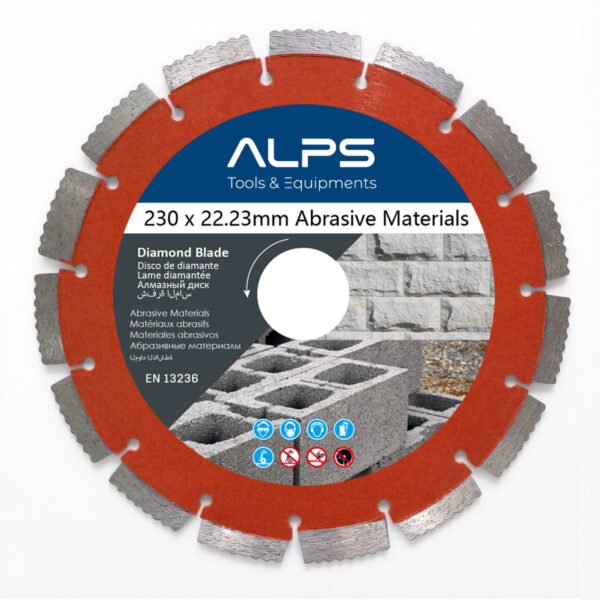

1. Product Overview

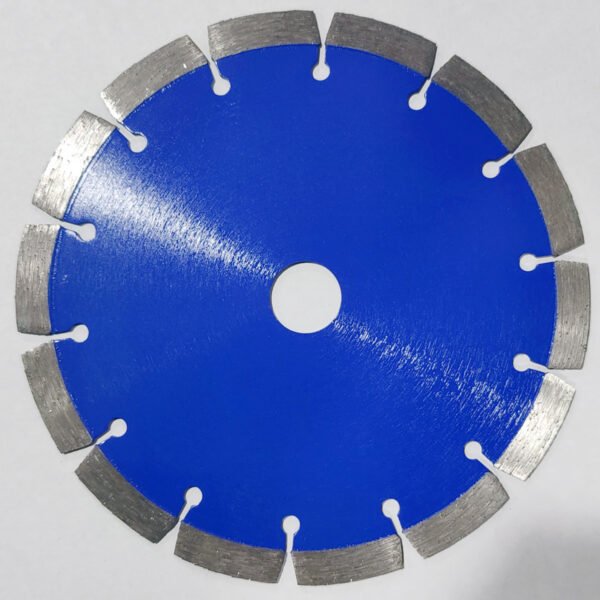

The Contractor Diamond Blade – General Purpose is a versatile and high – performance cutting tool engineered to meet the diverse needs of contractors, masons, DIY enthusiasts, and professionals in various construction and fabrication industries. It is designed to efficiently cut through a wide range of materials, making it an essential addition to any toolkit.

2. Key Features

2.1 Multi – Material Compatibility

- This diamond blade is suitable for cutting an extensive array of materials. It can effortlessly slice through concrete, whether it’s fresh or cured, making it ideal for construction projects involving concrete slabs, walls, and foundations.

- Bricks, blocks, and masonry materials are no match for this blade. Its design allows for clean and precise cuts, which is crucial for building walls, creating openings, or renovating brick – and – block structures.

- Natural stones such as slate, field stone, granite, and marble can be cut with ease. This makes it a great choice for both interior and exterior stonework, including countertops, flooring, and decorative stone installations.

- Ceramic tiles and porcelain tiles can also be accurately cut, making it useful for tiling projects in bathrooms, kitchens, and other areas.

2.2 High – Quality Diamond Technology

- The blade features a high – density distribution of premium – grade diamond particles. These diamonds are carefully selected for their exceptional hardness and durability. The diamond particles are embedded in a tough metal matrix, ensuring that they remain firmly in place during the cutting process, providing long – lasting cutting performance.

- The diamond – impregnated segments are designed to maintain their sharpness over time. This results in consistent cutting speed and reduces the need for frequent blade replacements, saving both time and money.

2.3 Enhanced Safety and Stability

- The blade is constructed with a robust steel core that provides excellent stability during operation. The steel core is precisely balanced to minimize vibration, which not only improves the quality of the cut but also reduces the risk of kickbacks, enhancing operator safety.

- The segments are securely attached to the core, either through advanced laser – welding or high – temperature brazing techniques. This ensures a strong bond between the segments and the core, preventing segment loss during high – speed cutting.

2.4 Versatile Design for Different Saws

- It is compatible with a wide variety of saws, including masonry saws, which are commonly used in construction for cutting large quantities of bricks and concrete.

- Brick saws can also be fitted with this general – purpose diamond blade, allowing for accurate and efficient brick cutting.

- Concrete saws, whether they are handheld, walk – behind, or stationary models, can benefit from the performance of this blade. It can handle the high – torque demands of concrete cutting and deliver smooth results.

- Cut – off saws, which are often used for quick and precise cuts in various materials, can be equipped with this blade for enhanced cutting performance.

- Circular saws and gas – powered saws are also suitable for use with this diamond blade, providing users with flexibility in choosing the right tool for the job.

3. Technical Specifications

Diameter:

Available in multiple sizes, typically ranging from 4 inches to 14 inches, to accommodate different cutting requirements and saw models.

Aperture (Arbor Size):

Standard arbor sizes such as 20mm and 25.4mm are commonly available, ensuring compatibility with most saws. Some blades may also come with adaptors or knock – out arbors to allow for easy adjustment to different arbor sizes.

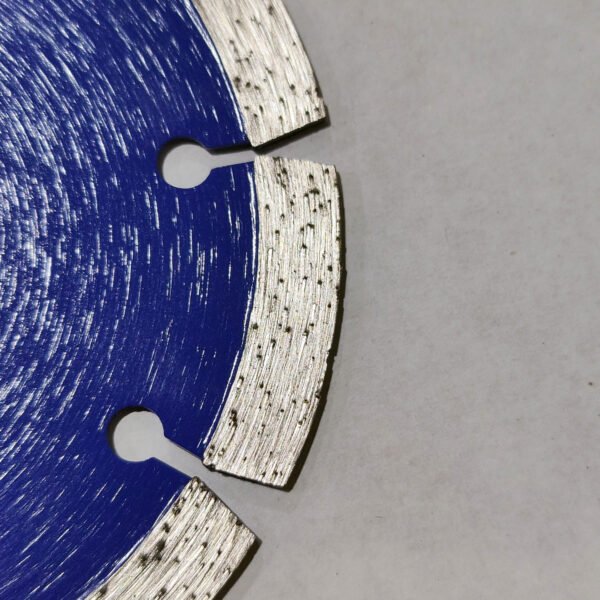

Segment Height:

The segment height varies depending on the blade size and intended application. For example, smaller blades may have a segment height of around 10mm, while larger blades for more heavy – duty cutting may have a segment height of 15mm or more. The taller segments provide longer – lasting cutting performance as they contain more diamond material.

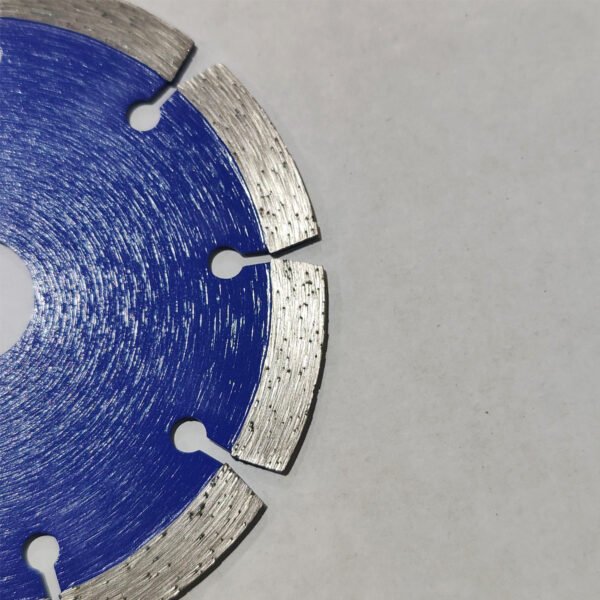

Segment Type:

Some blades feature continuous – rim segments, which are suitable for smooth and precise cuts, especially on materials like tiles and softer stones. Others may have turbo – segmented designs. The turbo – segmented blades have a series of evenly spaced grooves or teeth, which help to evacuate debris more efficiently during cutting. This results in faster cutting speeds and reduced heat build – up, making them ideal for cutting harder materials such as concrete and dense stones.

Maximum Rotational Speed:

The maximum RPM (revolutions per minute) varies based on the blade size. Smaller blades can typically handle higher RPMs, often in the range of 10,000 – 12,000 RPM, while larger blades may have a maximum RPM of around 6,000 – 8,000 RPM. It is crucial to operate the blade within the specified RPM range to ensure safe and optimal performance.

4. Applications

4.1 Construction Projects

- In building construction, this diamond blade is used for cutting concrete slabs to create openings for doors, windows, or utility installations. It can also be used to trim concrete edges and remove excess material.

- For masonry work, it is essential for cutting bricks and blocks to the required sizes for wall construction. The precise cuts achieved with this blade ensure a proper fit and strong bond between the masonry units.

- When constructing or renovating outdoor patios, walkways, or retaining walls made of stone or concrete pavers, this blade can be used to cut the pavers to the desired shape and size.

4.2 Renovation and Remodeling

- During home renovations, it can be used to cut through tiles when updating bathrooms, kitchens, or other tiled areas. The ability to make clean cuts helps to create a professional – looking finish.

- When remodeling a building, the blade can be used to cut through old concrete or masonry structures to make way for new installations or changes in layout.

4.3 Landscape and Hardscaping

- In landscape projects, it is useful for cutting natural stones such as granite or slate for the creation of decorative features like stone pathways, garden edging, or retaining walls.

- For hardscaping projects, it can cut concrete curbing or pre – cast concrete elements to the appropriate lengths and shapes.

5. Usage Tips

5.1 Equipment Compatibility

- Ensure that the diamond blade is compatible with your saw in terms of diameter, arbor size, and maximum RPM. Using an incompatible blade can lead to poor cutting performance, excessive vibration, and potential safety hazards.

- For high – powered saws, especially gas – powered ones, make sure the blade is designed to handle the high torque and speed. Check the manufacturer’s recommendations for the best blade – saw combination.

5.2 Cooling and Lubrication

- When cutting materials, especially hard and dense ones like concrete and stone, it is advisable to use water or a suitable cutting fluid for cooling and lubrication. This helps to reduce heat build – up in the blade, which can cause the diamond particles to degrade and the blade to wear out faster. Water also helps to flush away debris, resulting in a cleaner cut.

- For dry cutting applications, limit the cutting time to prevent overheating. If the blade starts to smoke or the cutting performance deteriorates, stop immediately and allow the blade to cool down.

5.3 Safety Precautions

- Always wear appropriate personal protective equipment (PPE) when using the diamond blade. This includes safety goggles to protect your eyes from flying debris, ear protection to reduce the impact of noise, and work gloves to protect your hands.

- Secure the material being cut firmly in place to prevent movement during cutting. This not only improves the quality of the cut but also reduces the risk of accidents.

- Follow the manufacturer’s instructions for blade installation and operation carefully. Do not exceed the recommended cutting depth or speed, as this can cause the blade to break or malfunction.

6. Quality Assurance

- Our Contractor Diamond Blade – General Purpose undergoes rigorous quality control checks during the manufacturing process. Each blade is inspected for proper diamond distribution, segment attachment, and overall balance.

- The blade is manufactured in accordance with international quality standards, such as ISO 9001, ensuring its reliability and performance.

- We offer a warranty on the blade, covering any defects in materials or workmanship. The length of the warranty may vary depending on the specific product and usage conditions. Please refer to the product documentation or contact our customer service for detailed warranty information.

7. Packaging and Storage

- The diamond blade is packaged in a sturdy cardboard box or a plastic – wrapped sleeve to protect it from damage during transportation and storage. The packaging also includes product information, such as the blade size, specifications, and usage instructions.

- Store the blade in a dry and cool place. Avoid exposing it to moisture, as this can cause rusting of the steel core. Keep the blade away from direct sunlight and extreme temperatures, as these can also affect the performance and lifespan of the diamond segments. When not in use, hang the blade on a hook or store it in a blade rack to prevent it from getting damaged or warped.

Reviews

There are no reviews yet.